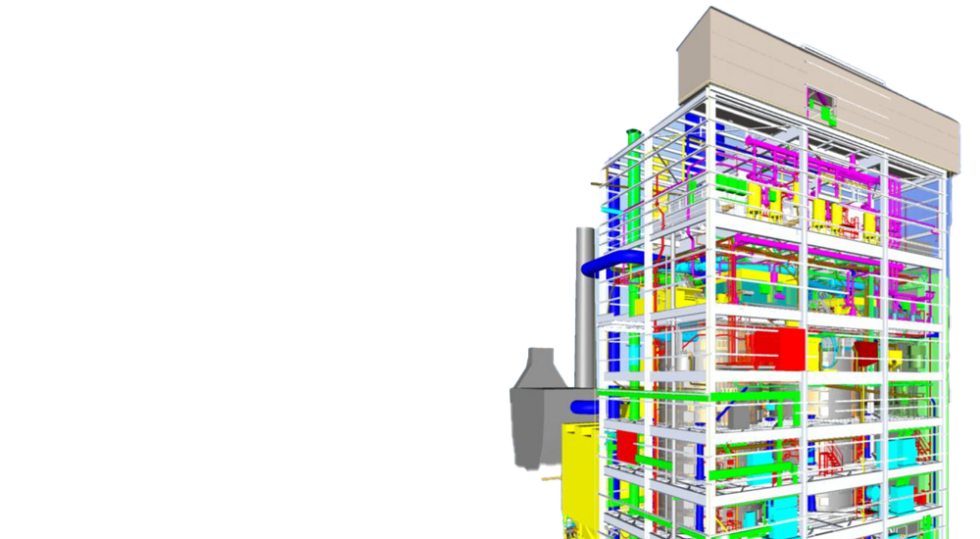

Our experts design and supply thermal processing reactors called Multiple Hearth Furnaces (MHF).

We offer 2 main technologies providing a full set of thermal solutions in several fields:

- The MHF NesaTorr™, a torrefaction furnace for light pyrolysis applications, such as biomass or waste processing

- The MHF NesaCore™, a high temperature furnace for deeper pyrolysis applications, ore concentrate roasting, minerals calcining, carbon or biomass activation, mineral concentrates screening, high-grade bio-coal or bio-coke production, …

- The MHF NesaBTF™ torrefaction technology, a pretreatment solution for the renewable fuel chain BioTfueL® process developed by the BioNext consortium.

Significant advantages of the John Cockerill MHFs

The duration of passage, the temperature profile, the atmosphere of solids or waste can be controlled with an extreme precision on each hearth, i.e. on each level of the John Cockerill thermal reactor.

This constitutes the most significant advantage of John Cockerill’s MHFs compared to more traditional types of ovens.

Over 150 John Cockerill multiple hearth furnaces are installed worldwide. They provide heavy duty performances, extended lifetime, high availability, and create value for our customers in the framework of circular economy and ecological transition.