D-Style Packaged Boilers: Proven technology

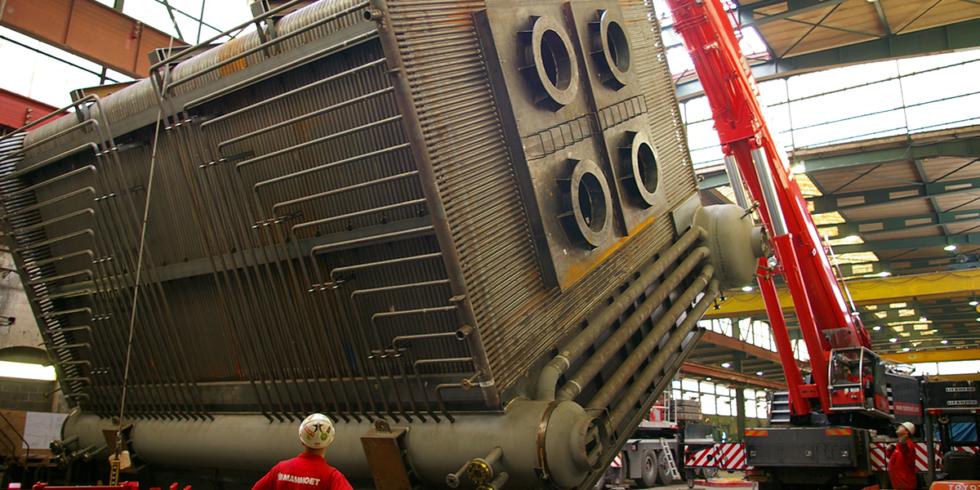

The Denapak is a self-supporting, two drum boiler with watercooled furnace walls.

- Meets steam equipment design, fabrication and safety requirements (ASME, PED 2014/68/EU or EN codes)

- Natural circulation design, includes integral steam and lower drums

- Flexible, reliable construction

- Seamless tubes form a thorough seal where they meet drums to eliminate heat-affected zones caused by welding

- Evaporator screen protect superheaters against direct radiation

- Optional installed feedwater preheater in the water drum to avoid flue gas condensation

- For increased efficiency, the Denapak is equipped with an economizer

- Preassembled and hydro-tested in the workshop prior to transportation

- For Larger capacity units shop fabrication will be optimized to reduce field erection cost

- Low NOx burners, flue gas recirculation and/or SCR systems can be provided to meet required emissions

Main Strengths

- Operational flexibility: 10 to 100% MCR (Maximum Continuous Rate)

- High thermal efficiency up to 97.5% (LHV)

- High availability up to 99.5%

- Compact boiler design

- Simplified foundation

- Guaranteed low NOx

- Maximized shop assembly

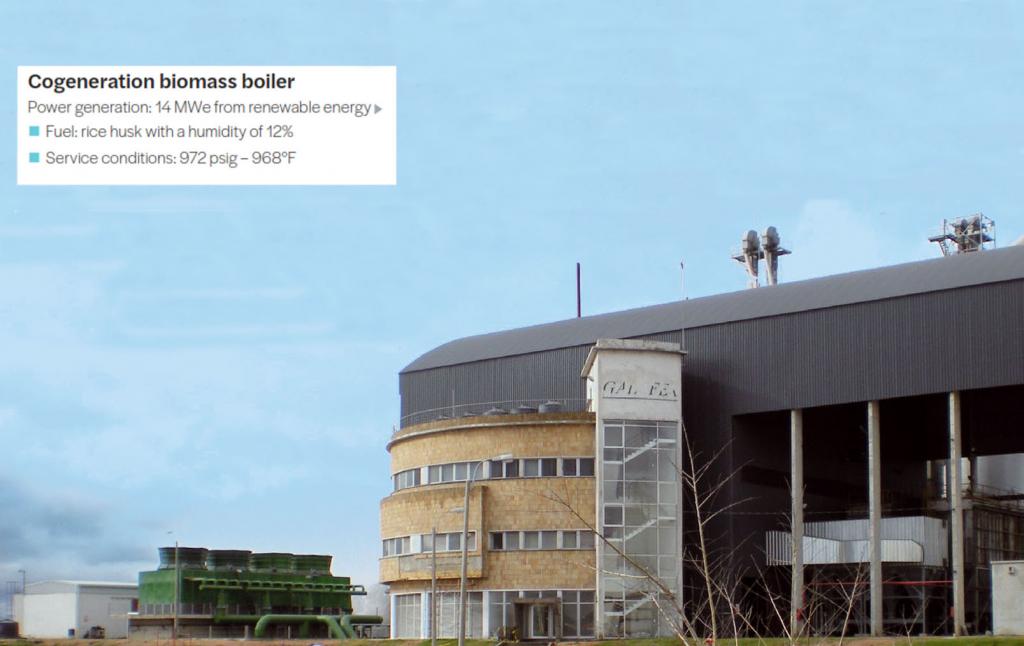

Operational data and References that speak for themselves

As John Cockerill’s reference list shows, the Denapak has proven to be a strong, and reliable industrial boiler choice for over 50 years. Click to upload the document.